MIL-DTL-19379C(SH)

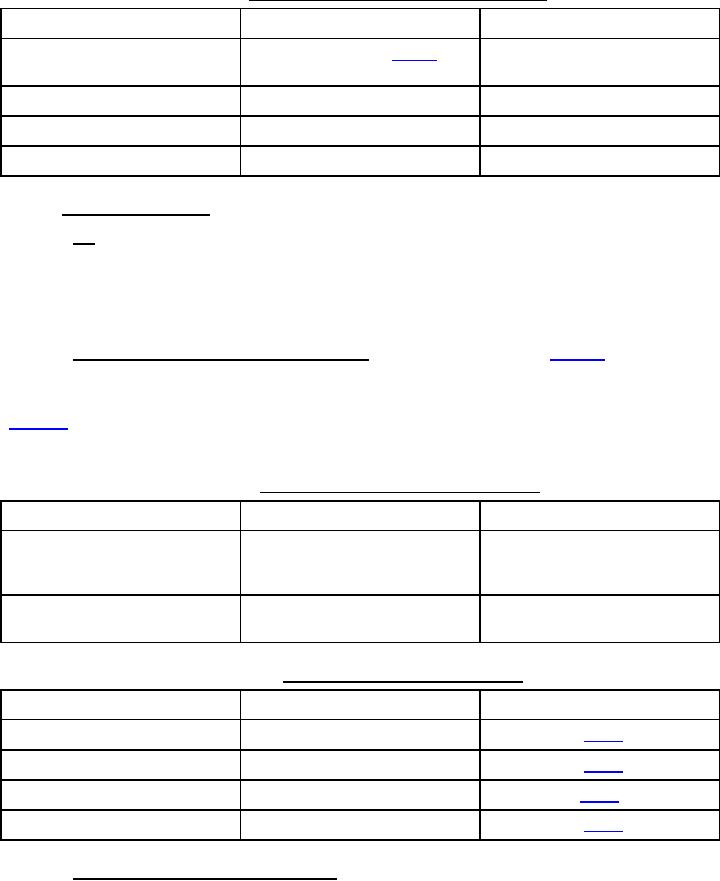

TABLE VI. Qualification tests on finished mounts, group two.

Property

Verification method

Requirement

1. Physical appearance, dimensions

803-1385824 and table X

and materials

2. Dynamic stiffness

3. Fatigue-drift

4. Delamination and porosity

4.3 Conformance inspection. Conformance inspection shall be performed on each production lot.

4.3.1 Lot. For the purpose of sampling for conformance inspection, a lot shall contain all mounts of one type

produced at the same time in the same facility under the same conditions with the same batch of rubber compound.

A lot number shall be assigned to the mounts and shall not be repeated in any one quarter. The lot number with

elastomer cure date (quarter, year) shall be traceable to the rubber batch number, manufacturing/process control

records, and conformance documentation. The lot number along with cure date shall be permanently marked on

each mount (refer to 803-1385824) and be included on all shipping documents, packages, and shipping containers.

4.3.2 Conformance inspection of the rubber compound. The specimens identified in table VII shall be prepared

for each mount lot produced. The specimens shall be made from the same batch of rubber compound mixed for the

manufacture of mounts in the lot. The specimens shall be certified to be of the same material and equivalent cure as

the corresponding lot of finished mounts. These specimens shall be subjected to verification tests specified in

table VIII to determine compliance with 3.4.2.2. If any specimens tested fail to meet any requirement, all mounts in

the lot represented by that specimen shall be rejected.

TABLE VII. Rubber specimens for conformance inspection.

Quantity

Specimen description

Property to be measured

3

ASTM D412, Die C

Tensile strength and ultimate

from sheets 0.08±0.01 by 6 by 6

elongation, specific gravity

inches

1

Cylinder: 0.50±0.02 inch height by

Hardness

1.14±0.02 inch diameter

TABLE VIII. Conformance tests on rubber specimens.

Verification test

Test method

Requirement

1. Initial tensile strength

2. Initial ultimate elongation

3. Specific gravity

4. Hardness

4.3.3 Conformance inspection of finished mounts. Mounts shall be sampled and subjected to verification tests

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business