MIL-DTL-19379C(SH)

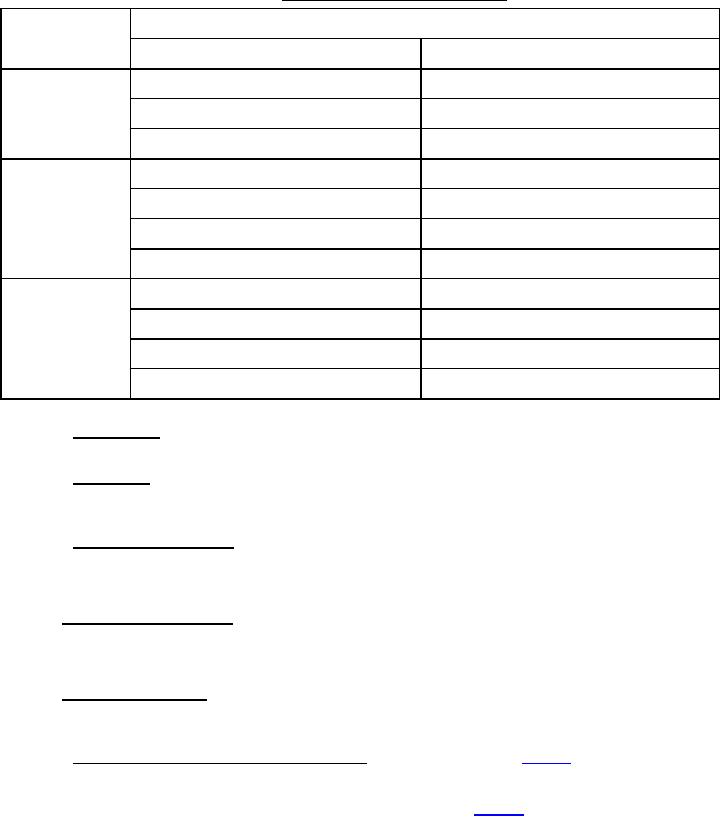

TABLE II. Axial dynamic stiffness requirements.

Requirement limits

Mount type

Axial load (lb)

Dynamic stiffness (lb/in)

9

190 to 230

11M15

12

181 to 224

15

166 to 214

15

283 to 398

18

278 to 403

11M25

22

269 to 404

25

260 to 403

25

459 to 590

33

438 to 562

10M50

42

429 to 557

50

414 to 553

3.5.3 Static strength. When tested in accordance with 4.4.2.2, mounts shall not show any separation, break in

or between component parts, debonding, or permanent deformation of metal parts.

3.5.4 Fatigue-drift. When tested in accordance with 4.4.2.3, mounts shall not show any indication of damage to

the resilient element, rubber-to-metal bond, and metal parts. The drift occurring to the type 11M15, 11M25, and

10M50 mounts during these tests shall not exceed 0.017, 0.025, and 0.040 inch, respectively.

3.5.5 Delamination and porosity. When tested in accordance with 4.4.2.4, the rubber shall not show evidence

of porosity, separation into distinct layers, or laminations.

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are classified as follows:

a.

Qualification inspection (see 4.2).

b.

Conformance inspection (see 4.3).

4.2 Qualification inspection. The inspection and tests specified herein are required to qualify mounts produced

by a manufacturer for inclusion in the Qualified Products List (QPL) for this specification. Refer to 3.1 and 6.3.

Qualification inspection shall be performed on finished mounts and the rubber compound.

4.2.1 Qualification inspection of the rubber compound. Specimens described in table III shall be produced

from the rubber compound which is mixed for the manufacture of all mounts subjected to qualification inspection.

The manufacturer shall certify that the specimens are of the same material and equivalent cure as the mounts tested

for qualification. These specimens shall be subjected to the tests specified in table IV to determine compliance with

3.4.2.2. If any specimens tested fail to meet any requirement, all mounts manufactured for qualification from rubber

batches represented by that specimen shall be rejected.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business