MIL-DTL-17191E(SH)

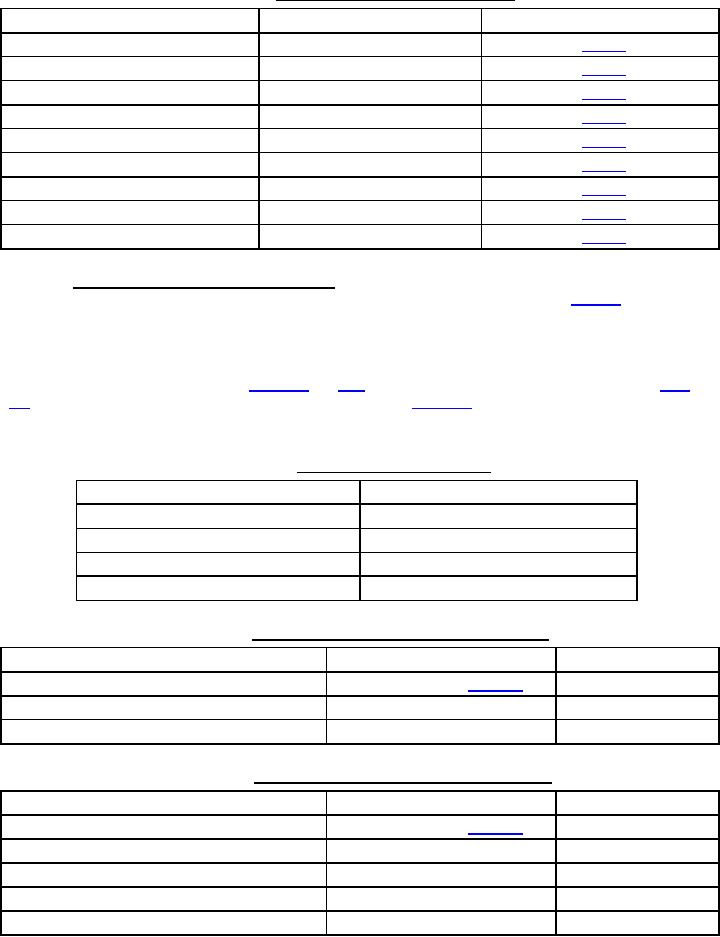

TABLE V. Qualification tests on rubber specimens.

Property

Verification method

Requirement

1. Initial tensile strength

3.3.3.2 (table II, no. 1)

2. Initial ultimate elongation

3.3.3.2 (table II, no. 2)

3. Tensile strength after oven aging

3.3.3.2 (table II, no. 1)

4. Ultimate elongation after oven aging

3.3.3.2 (table II, no. 2)

5. Compression set after oven aging

3.3.3.2 (table II, no. 3)

6. Cold compression set

3.3.3.2 (table II, no. 3)

7. Adhesion to metal

3.3.3.2 (table II, no. 4)

8. Hardness

3.3.3.2 (table II, no. 5)

9. Volume change in oil

3.3.3.2 (table II, no. 6)

4.2.2 Qualification inspection of finished mounts. If rubber specimens meet all requirements associated with

qualification inspection (see 4.2.1), then four of each of the finished mount types specified in table VI shall be

manufactured and subjected to testing (sixteen mounts total). If the manufacturer is seeking qualification for only

one mount type, then only four finished mounts of that type shall be subjected to qualification inspection. The

manufacturer shall certify that the finished mounts are molded from the same batch of rubber compound as the

specimens that have successfully passed qualification. Four mounts of each type specified shall undergo

qualification testing in accordance with tables VII and VIII. Two mounts shall be tested in accordance with table

VII. The remaining two mounts shall be tested in accordance with table VIII. Mounts shall be tested in the

sequence shown in each of the two tables.

TABLE VI. Mount samples for qualification.

Mount type

Rubber compound (4.2.1)

15P150A or 15P400A

Class A

15P220A or 15P550A

Class B

15P300A or 15P700A

Class C

15P1200A or 15P2000A

Class D

TABLE VII. Qualification tests on finished mounts, group one.

Property

Verification method

Requirement

1. Physical appearance, dimensions, and materials

803-1385777 and table XII

2. Dynamic stiffness

3. Static strength

TABLE VIII. Qualification tests on finished mounts, group two.

Property

Verification method

Requirement

1. Physical appearance, dimensions, and materials

803-1385777 and table XII

2. Drift

3. Dynamic stiffness

4. Fatigue

5. Delamination and porosity

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business