MIL-DTL-17191E(SH)

3.2 Mount design. Mounts shall meet the requirements of this specification and be constructed in accordance

with 803-1385777. S9073-A2-HBK-010 contains comprehensive test data showing performance characteristics

acquired during the development of each mount type. Included are damping values, static load-deflection, and

dynamic stiffness performance data. This data may be useful to the manufacturer attempting to construct mounts in

accordance with this specification. Refer to 2.4.

3.3 Materials.

3.3.1 Recycled, recovered, environmentally preferable, or biobased materials. Recycled, recovered,

environmentally preferable, or biobased materials should be used to the maximum extent possible, provided that the

material meets or exceeds the operational and maintenance requirements, and promotes economically advantageous

life cycle costs.

3.3.2 Metal. Mount metal components shall be manufactured from steel or manganese bronze as specified

(see 6.2). Metal shall be in accordance with the appropriate specification listed in 803-1385777; substitutions are

permitted when approved by NAVSEA. Components shall be formed into shape and finished in accordance with

the dimensions and allowable tolerances specified in 803-1385777. Metal components shall be protected against

corrosion by seawater and other atmospheric conditions encountered in service. Unless otherwise specified

(see 6.2), the minimum protective treatment shall be equivalent to that specified in 803-1385777.

3.3.3 Rubber.

3.3.3.1 Resilient element. The resilient element shall be fabricated of oil resistant compounds utilizing

polymerized chloroprene as the basic material. It shall be molded to the prescribed form and completely bonded to

all metal components of the mount with which it makes contact, as shown in 803-1385777. The rubber compounds

for the resilient elements shall be furnished in four classes. The mount type shall be fabricated from the

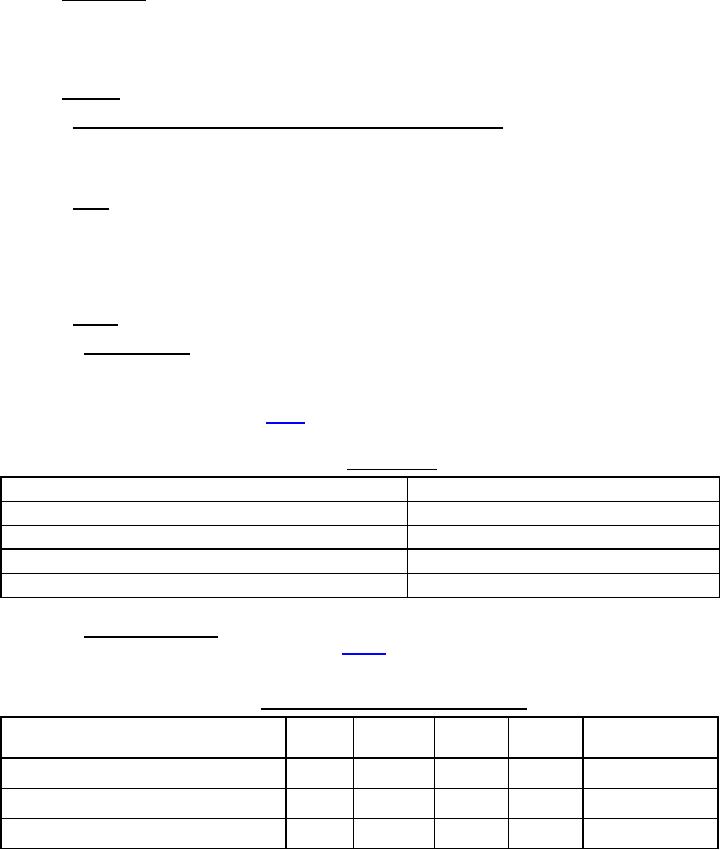

corresponding rubber compound shown in table I.

TABLE I. Rubber classes.

Mount type

Rubber compound

15P50A, 15P150A, 15P400A, 15P400B

Class A

15P100A, 15P220A, 15P550A, 15P550B, 15P800A, 15P800B

Class B

15P300A, 15P700A, 15P700B, 15P1000A, 15P1000B

Class C

15P1200A, 15P1200B, 15P2000A, 15P2000B

Class D

3.3.3.2 Physical requirements. Physical properties of the cured rubber compound used in the resilient element

shall conform to the physical requirements specified in table II.

TABLE II. Physical requirements of rubber compounds.

Verification

Property

Class A

Class B

Class C

Class D

method

1. Tensile strength (minimum), psi

-Before aging

2200

2500

2800

2900

-After aging at 194 °F for 46 hours

2100

2400

2700

2800

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business