MIL-DTL-17191E(SH)

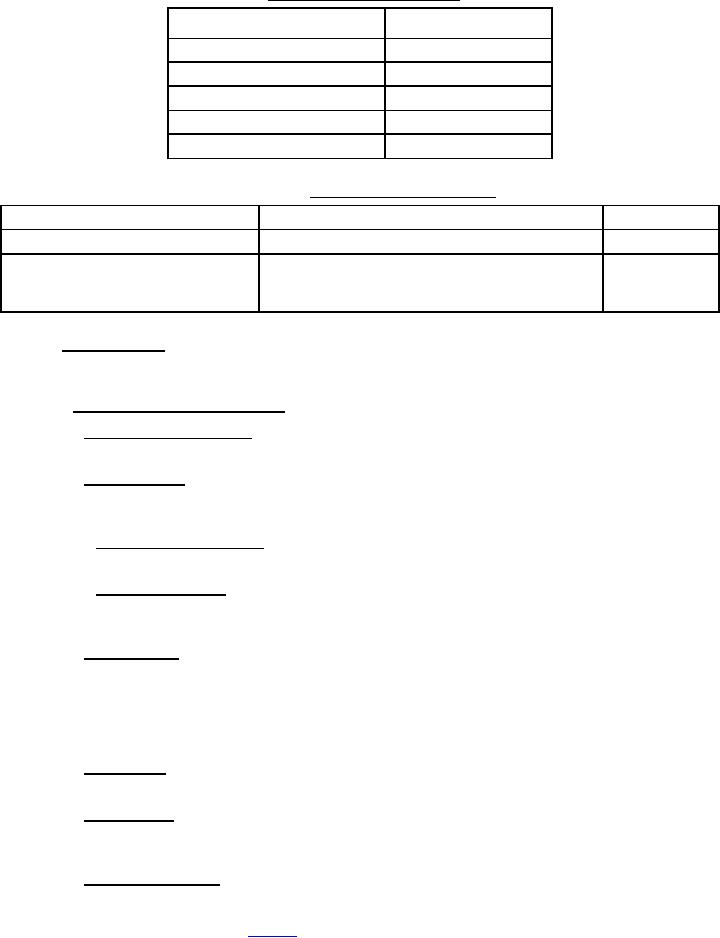

TABLE XIII. Sampling for conformance tests Continued.

Number of mounts in a lot

Sample quantity

181 to 300

8

301 to 500

10

501 to 800

12

801 to 1300

15

1301 to 3200

20

TABLE XIV. Conformance verification tests.

Verification test

Test method

Requirement

1. Dynamic stiffness

2. Static strength test in axial direction

Axial strength test shall be in accordance with

4.4.2.2.2 except the peak load obtained shall be from

Curve 2 for all four loading-unloading cycles.

4.4 Verification tests. Unless otherwise specified in a particular test procedure, all tests shall be conducted at

an ambient temperature of 80±10 °F. Within this range, the temperature from the beginning to the end of any one

test shall not vary more than ±5 °F.

4.4.1 Test methods for rubber specimens.

4.4.1.1 Tensile and elongation tests. For tensile strength and elongation, the method of tests shall be in

accordance with ASTM D412, Method A, using three Die C test specimens.

4.4.1.2 Compression set. For compression set tests, rubber specimens with a hardness less than or equal to

44 durometer shall be compressed 40 percent. Rubber specimens with a hardness greater than or equal to

45 durometer shall be compressed 30 percent.

4.4.1.2.1 Compression set after aging. Compression set shall be determined on two test specimens in

accordance with ASTM D395, Method B, except aging shall be as specified in 4.4.1.3.

4.4.1.2.2 Cold compression set. Cold compression set shall be determined in accordance with ASTM D1229

on two rubber specimens, except exposure shall be 30±2 °F for 94±½ hours. The compression set shall be

determined 30 minutes after the compressive load is released.

4.4.1.3 Oven aging test. The specimens for tensile, ultimate elongation, and compression set tests shall be

given an accelerated aging test by subjecting them to dry circulating air at a temperature of 194±2 °F for

46±¼ hours. Final determination of aged tensile and elongation specimens shall be made not less than 10 hours or

more than 48 hours after removal from the oven. Tensile and elongation tests on unaged specimens shall be made

immediately prior to, and on the same machine as, the tensile tests on the aged specimens. Refer to ASTM D573 for

guidance.

4.4.1.4 Hardness test. Hardness (Shore A) of the 0.49±0.02-inch thick specimens shall be determined in

accordance with ASTM D2240. A 3-second reading shall be taken to determine conformance.

4.4.1.5 Swelling in oil. Volume change in oil shall be determined in accordance with ASTM D471, except the

three specimens shall be immersed for a period of 46±¼ hours at 73±4 °F. The specimen shall be immersed in

reference oil IRM 903 of ASTM D471.

4.4.1.6 Adhesion to metal test. The adhesion tests shall be in accordance with Method A of ASTM D429.

Three specimens of the rubber compound bonded to metal shall be tested and results averaged to determine

compliance. Specimens shall have the same surface preparation, adhesive system, metal type, and bonding method

as used in the finished mount. Refer to table IV for specimen description.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business