MIL-DTL-17191E(SH)

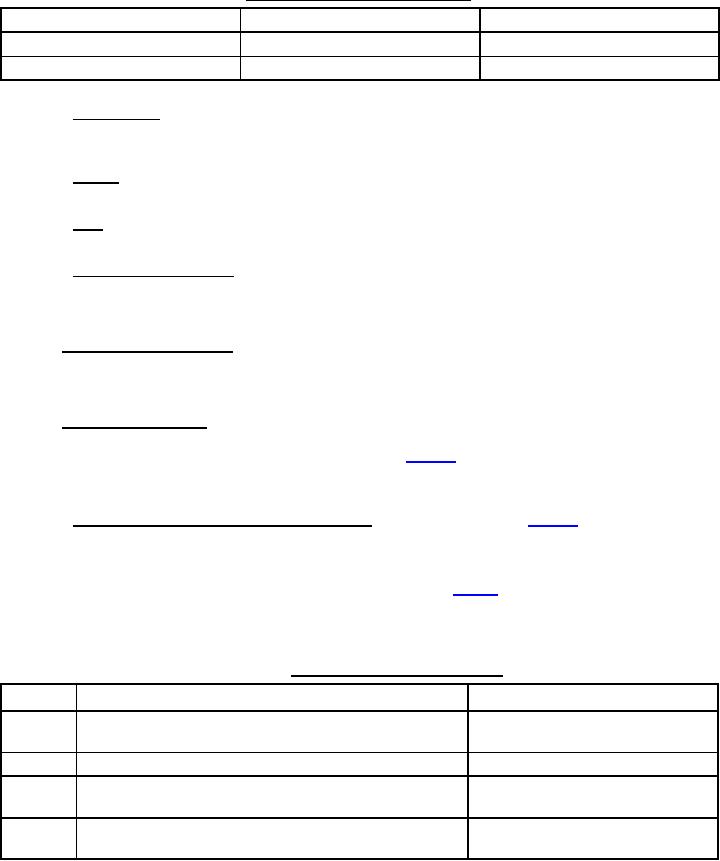

TABLE III. Axial dynamic stiffness requirements Continued.

Mount type

Axial load (lb)

Dynamic stiffness (lb/in)

15P1200A and 15P1200B

1200

19931 to 36483

15P2000A and 15P2000B

2000

33219 to 60805

3.4.3 Static strength. Mounts, when tested in accordance with 4.4.2.2, shall not show any appreciable

permanent deformation of metal parts or damage such as separation, tears, cracks, or breaks in or between

component parts.

3.4.4 Fatigue. Mounts, when tested in accordance with 4.4.2.3, shall not show evidence of failure of the

resilient element, bond, and metal parts.

3.4.5 Drift. The mounts shall not have a loss in height greater than 0.012 inch when tested in accordance with

3.4.6 Delamination and porosity. When tested in accordance with 4.4.2.5, the resilient element shall not show

evidence of porosity or separation into distinct layers or laminations.

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are classified as follows:

a.

Qualification inspection (see 4.2).

b.

Conformance inspection (see 4.3).

4.2 Qualification inspection. Qualification inspection shall be performed on finished mounts (see 4.2.2) and

their associated rubber compounds (see 4.2.1). Refer to 3.1 and 6.3. If the manufacturer is seeking qualification for

all mount types (see 1.2.1), then the four mount types specified in table VI shall be subjected to qualification

inspection. If the manufacturer is seeking qualification for one mount type, then only that mount type and

associated rubber compound shall be subjected to qualification inspection.

4.2.1 Qualification inspection of the rubber compounds. Specimens described in table IV shall be produced

from the four classes of rubber compounds which are mixed for the manufacture of mounts subjected to

qualification inspection. Refer to 4.2.2 for mount types subjected to qualification. The manufacturer shall certify

that the specimens are of the same material and equivalent cure (and bond) as the mounts to be tested for

qualification. These specimens shall be subjected to the tests specified in table V to determine compliance with

3.3.3.2. If all test specimens meet all requirements, then mounts shall be tested for qualification in accordance with

TABLE IV. Rubber specimens for qualification.

Quantity

Specimen description

Property to be measured

6

ASTM D412, Die C: from sheets 0.08±0.01 by 6 by 6 inches

Tensile strength and ultimate

elongation (initial and aged)

3

Rectangular: 0.08±0.01 by 1 by 2 inches

Resistance to oil

3

Cylinder: 0.125±0.005-inch thickness by 1.597±0.005-inch

Adhesion to metal

diameter bonded to metal plates

4

Cylinder: 0.49±0.02-inch thickness by 1.14±0.02-inch

Hardness and compression set

diameter

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business