MIL-DTL-18001L

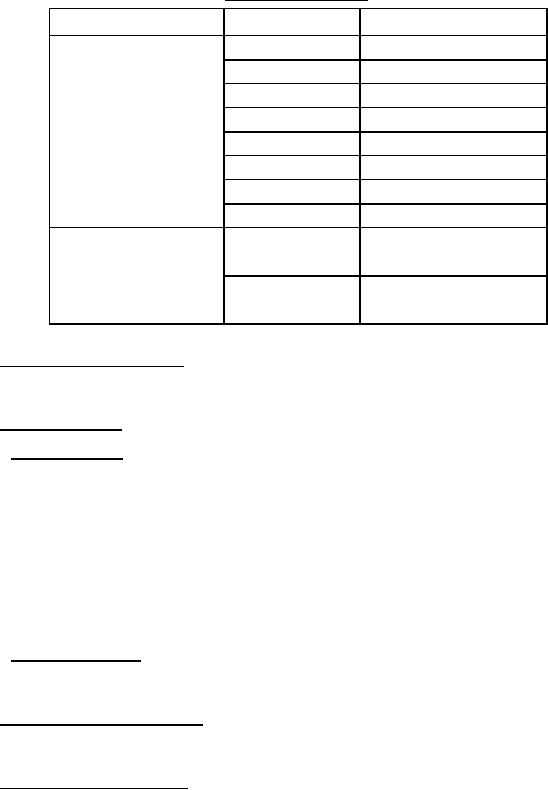

TABLE IV. National stock numbers Continued.

Anode type

Size (inches)

National stock number

1.050 in dia

5342-00-813-6056

0.840 in dia

5342-00-576-1749

0.840 in dia

5342-00-664-0531

0.840 in dia

5342-00-796-4354

ZRN

0.840 in dia

5342-00-813-6055

0.675 in dia

5342-00-813-6054

0.540 in dia

5342-01-356-6381

0.405 in dia

5342-00-813-6053

24 x 48 x 0.5 in

5342-00-290-3793

ZPN

24 x 48 x 1 in

5342-01-358-4414

6.4 General forms and dimensions. When material is ordered in the form of slabs, bars, discs, or rods, it is to

be understood that these terms refer merely to the general form and dimensions of the material, and do not have any

technical significance as to the methods of manufacture.

6.5 Sampling procedure.

6.5.1 Drilling procedure. The drilling for chemical analysis should be made with a special nonferrous drill in a

clean location (used only for that purpose). The drilling bits should be kept clean of dirt, grit, and other foreign

matter; kept properly sharpened; and used only for sampling purposes. After each use, the drilling bit should be

immersed in a degreasing solvent and wiped dry with a clean rag. The drilling bits, when not in use, should be

stored in an inhibited lubricating oil. The inhibited lubricating oil should be kept in a covered glass container

provided with an air vent. The drilling bits should be wiped dry with a clean rag prior to use. Samples should be

taken with a dry drill. If automatic power drilling equipment is available, a solid tungsten carbide or Tantung twist

drill bit about ½ inch (12.7 millimeters) in diameter is suitable. Where a hand-held power drill is used, the samples

should be taken by drilling with a solid tungsten carbide or Tantung twist drill bit about ¼ inch (6.35 millimeters) in

diameter. A smaller drill bit may be used where the size of the anode does not permit using the specified diameters.

The drills may be used at high speeds and feeds.

6.5.2 Machining procedure. The chips for chemical analysis should be made with a special nonferrous tool in a

place which has been cleaned for that specific purpose. Instructions specified in 6.5.1 apply to the use and care of

this tool.

6.6 Sub-contracted material and parts. The packaging or preparation for delivery of requirements of referenced

documents listed in section 2 do not apply when material and parts are acquired by the contractor for incorporation

into the equipment and lose their separate identity when the equipment is shipped.

6.7 Subject term (key word) listing.

Corrosion

Disc

Galvanic

Plate

Rod

Slab

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business