CONTOUR DEFINITION POINTS (SEE NOTE 2)

Q

C

G

J

B

A

D

E

F

H

K

L

M

N

P

R

IMPERIAL (IN)

.87

.93

.63

1.38

1.50

1.48

1.43

1.35

1.25

1.43

1.50

1.46

1.35

1.11

1.17

1.11

METRIC (MM)

36.3

38.1

37.1

34.3

29.7

23.6

16.0

35.1

38.1

37.6

36.3

34.3

31.7

28.2

28.2

22.1

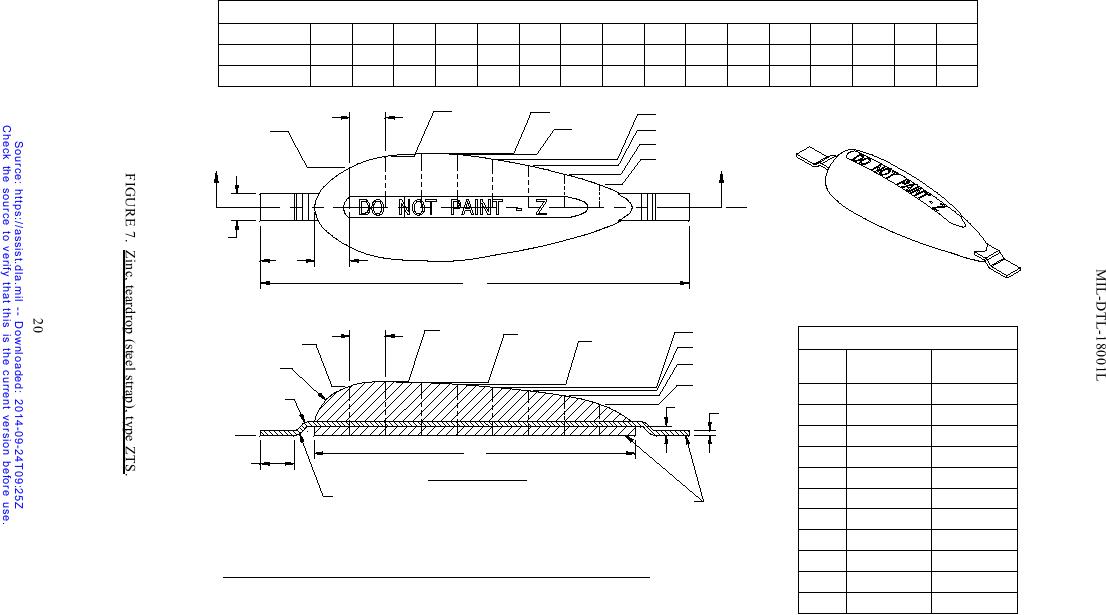

7X

B

C

E

D2

D

F

A

G

H

A

A

0.00

D6

D5

D2

D4

7X

K

N

L

TABLE OF DIMENSIONS

M

J

D2

P

IMPERIAL

METRIC

Q

DIM

CAST ANODE

(INCH)

(MM)

R

9.00±.13

228.6±3.3

D1

4X R1

D8

D7

1.00

25.4

D2

0.00

D3

±.13

±3.3

D1

12.00±.13

304.8±3.3

D4

2X D9

SECTION A-A

D5

1.50±.13

38.1±3.3

STEEL STRAP

D6

.75±.13

19±3.3

STRAP FEET FLUSH WITH

CASTING BOTTOM W/IN D10

.13±.06

3.3±1.5

D7

.25±.13

6.4±3.3

D8

D9

.94±.13

23.9±3.3

SKETCH C: TEARDROP SHAPE (STEEL STRAP), TYPE ZTS

±.13

±3.3

D10

1. MINIMUM WEIGHT: 5.0 LB / 2.3 KG

2.8 MIN

.11 MIN

R1

2. CONTOUR TOLERANCE IS ±D3 MEASURED NORMAL TO SURFACE.

CONTOUR SHALL BE HYDRODYNAMICALLY FAIR.

3. ANODE MAY BE CAST WITH EXPOSED FACE IN THE UP OR DOWN POSITION.

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business